The Role of Foam Control in Enhancing Item Quality and Effectiveness

Foam control is an often-overlooked yet essential component in the pursuit of product high quality and functional efficiency throughout diverse markets. This conversation will explore the diverse effect of foam on both item honesty and manufacturing processes, elevating necessary concerns about the techniques that can be used to enhance foam control.

Understanding Foam Development

Foam formation is an intricate sensation that can significantly affect product high quality and operational performance across different industries. It takes place when gas bubbles become trapped in a liquid, bring about the production of a foamy structure. Numerous elements contribute to this procedure, including the chemical and physical buildings of the liquid, the visibility of surfactants, and the conditions under which blending happens. Understanding these variables is critical for handling foam properly.

The liquid's thickness and surface tension play critical roles in foam stability. Surfactants, as an example, can reduce surface area stress, advertising bubble development but likewise boosting foam security, which can be problematic in specific applications. In addition, mechanical agitation, temperature changes, and the existence of contaminations can aggravate foam generation, making it vital to check these aspects during production procedures.

Industries such as food and beverage, pharmaceuticals, and chemical manufacturing must be particularly alert regarding foam control. By understanding the underlying systems of foam development, companies can carry out targeted strategies to mitigate its effects, thus maintaining operational performance and guaranteeing regular item performance.

Effect On Item High Quality

The presence of foam can considerably compromise product quality throughout various markets. In manufacturing processes such as food and beverage, pharmaceuticals, and cosmetics, extreme foam can result in irregular product solutions. As an example, in food manufacturing, foam might catch air, influencing appearance and taste, which can inevitably change customer perception and fulfillment.

Additionally, foam can hinder the harmony of finishings and paints, resulting in defects like bubbles and unequal finishes. In pharmaceutical applications, foam can hinder the precise dosing of fluid medications, possibly impacting healing effectiveness and patient safety and security. These quality problems not only lessen the end item's appeal however can likewise cause expensive recalls and damages to brand credibility.

Additionally, the existence of foam can make complex high quality control measures, making it hard to attain exact measurements and regular outcomes. Efficient foam control not just mitigates these risks however likewise improves total item top quality by guaranteeing that formulas satisfy rigid sector criteria. By buying foam control techniques, business can secure their items, boost customer fulfillment, and preserve an affordable edge in the market.

Functional Difficulties From Foam

Efficient procedures in numerous sectors can be seriously interrupted by the existence of foam, which positions several challenges throughout production processes. Foam can hinder mixing and reaction times, hindering the efficiency of chemical processes. In industries such as food and beverage, foam development can bring about imprecise fill degrees, resulting in product waste and variances in product packaging.

In atmospheres where health is extremely important, such as drugs and food processing, foam can make complex cleaning protocols, developing concealed reservoirs for impurities. This not just raises top quality worries but additionally can cause compliance concerns with regulative standards.

Furthermore, the emotional effect on drivers can not be neglected; excessive foam can produce a disorderly workplace, causing decreased morale and productivity. In recap, addressing the functional obstacles presented by foam is crucial to keeping efficiency and item high quality in different sectors.

Techniques for Reliable Foam Control

Exactly how can markets effectively reduce the difficulties postured by foam? Reliable foam control approaches are necessary for improving product top quality and functional effectiveness.

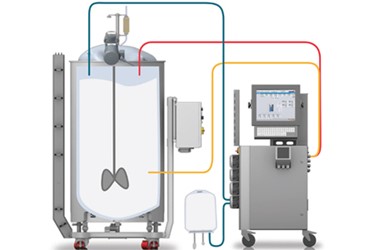

In addition to chemical solutions, procedure optimization plays a crucial duty in foam administration. Industries can examine and change parameters such as blending speed, temperature, and stress to minimize foam generation. Applying devices modifications, like mounting foam-breaking gadgets or adjusting storage tank design, can further aid minimize foam degrees.

Routine monitoring and evaluation of foam behavior within manufacturing procedures are likewise crucial. Using innovative sensors and analytics can supply real-time data, allowing for timely treatments and adjustments. Personnel training is just as crucial; guaranteeing that workers are experienced concerning foam characteristics and control techniques can lead to aggressive foam monitoring.

Instance Researches and Market Applications

While numerous industries face unique obstacles connected to foam control, situation research studies reveal that customized strategies can significantly boost both item quality and operational performance. In the pharmaceutical market, for instance, a leading producer implemented a custom foam control method that decreased foam formation during fermentation procedures. This advancement not only improved return by 15% yet likewise lessened contamination risks, ensuring greater item stability.

Likewise, in the food and beverage sector, a major dairy manufacturer faced too much foam during pasteurization - Foam Control. By presenting a specialized antifoam representative, they decreased handling time by 20%, which directly converted to enhanced throughput and minimized energy intake. The application of foam control measures ensured regular product structure and preference, strengthening brand name a knockout post loyalty

In the chemical production sector, a situation study highlighted the successful application of foam control in wastewater therapy processes. The application of a real-time surveillance system enabled drivers to adjust antifoam dosage dynamically, leading to a 30% reduction in chemical use and improved effluent top quality.

These case research studies illustrate the diverse applications of foam control throughout sectors, emphasizing its essential role in improving item high quality and functional effectiveness.

Verdict

In final thought, reliable foam control is integral to improving item high quality and functional effectiveness throughout numerous industries. By addressing foam development, businesses can reduce the adverse impacts on solutions, structure, and dosing precision. Implementing targeted foam management strategies not just minimizes processing delays and waste but additionally boosts tools dependability. Ultimately, prioritizing foam control adds to boosted performance, protecting brand credibility, and increasing client fulfillment, highlighting its value in quality control within producing processes.

Foam control is an often-overlooked yet essential element in the pursuit of item top quality and operational efficiency throughout varied markets. Personnel training is equally essential; making sure that personnel are educated regarding foam dynamics and control strategies can lead to proactive foam monitoring.

While lots of industries encounter special challenges connected to foam control, case researches reveal that customized methods can significantly boost both product top quality and operational efficiency (Foam Control). more information In the pharmaceutical market, for instance, a leading maker implemented a custom-made foam control technique that lowered foam formation throughout fermentation processes.In verdict, efficient foam control web link is indispensable to improving product top quality and operational effectiveness across different industries